Top 10 Automatic Liquid Packaging Machines for Efficient Production

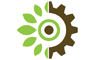

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. One key component that facilitates these factors is the automatic liquid packaging machine. These advanced devices streamline the process of filling and sealing liquid products, offering significant advantages over manual operations. As businesses strive to enhance productivity, the reliance on automated solutions has become increasingly clear.

The top 10 automatic liquid packaging machines available today exemplify the technological innovations that have transformed the industry. Designed to cater to a wide range of liquids, from beverages to sauces, these machines not only increase output rates but also ensure consistent quality. Furthermore, with advancements in automation and control systems, these machines boast improved reliability and reduced downtime, making them invaluable assets in modern production lines.

As we delve into the details of the leading automatic liquid packaging machines, it becomes evident that their integration into production processes offers compelling benefits. Whether for small enterprises or large-scale manufacturers, understanding the capabilities and features of these machines is essential for optimizing operations and staying competitive in the market.

Overview of Automatic Liquid Packaging Machines

Automatic liquid packaging machines have revolutionized the production process across various industries, enhancing efficiency and consistency in packaging. These machines are designed to handle a wide range of liquid products, including beverages, sauces, and chemicals, ensuring accurate filling, sealing, and labeling. According to industry reports, the global market for liquid packaging machines is projected to grow significantly, with a compound annual growth rate (CAGR) of approximately 5.3% from 2022 to 2028. This growth is driven by increasing demand for efficient packaging solutions that meet consumer needs for convenience and sustainability.

When selecting automatic liquid packaging machines, it’s vital to consider various factors such as speed, flexibility, and the type of liquid being packaged. For instance, machines equipped with advanced sensors can accurately detect fill levels, preventing overflows and minimizing product waste. Additionally, many modern machines offer easy changeover capabilities, allowing businesses to switch between different product types with minimal downtime.

Tips: Always assess the volume and viscosity of the liquids you intend to package, as this will influence the choice of machinery. Moreover, investing in machines that comply with industry standards can enhance your operational reliability and ensure product safety. Regular maintenance of packaging equipment also plays a crucial role in sustaining productivity levels and prolonging the lifespan of the machines.

Key Features to Consider in Liquid Packaging Machines

When selecting an automatic liquid packaging machine, several key features are crucial for ensuring efficient production and maintaining high-quality standards. First and foremost, the machine's speed and efficiency are paramount. According to a recent report by MarketsandMarkets, the demand for automated packaging machinery is projected to grow by over 6% annually, driven by the need for faster production rates. Machines that can achieve output speeds of 60 to 100 containers per minute are becoming industry standards, allowing manufacturers to keep up with increasing market demands.

Another critical feature is flexibility in packaging options. Modern machines are designed to handle various container sizes and types, accommodating everything from bottles to pouches. The ability to easily switch between different packaging formats without extensive downtime is essential for manufacturers aiming to remain competitive. Additionally, integrating smart technology and IoT capabilities into these machines can significantly enhance operational efficiencies. For instance, a recent study highlighted that companies using smart packaging solutions reported a 20% reduction in maintenance costs and a notable improvement in overall process visibility.

Finally, it's essential to consider the machine's material compatibility and hygiene standards, especially in industries like food and beverage. Research indicates that over 50% of packaging failures can be attributed to material incompatibility, making it vital for machines to work with a range of materials safely. Adhering to stringent hygiene regulations not only ensures product safety but also builds consumer trust, ultimately affecting a brand's market position.

Top 10 Automatic Liquid Packaging Machines - Efficiency Comparison

Top Brands in Automatic Liquid Packaging Technology

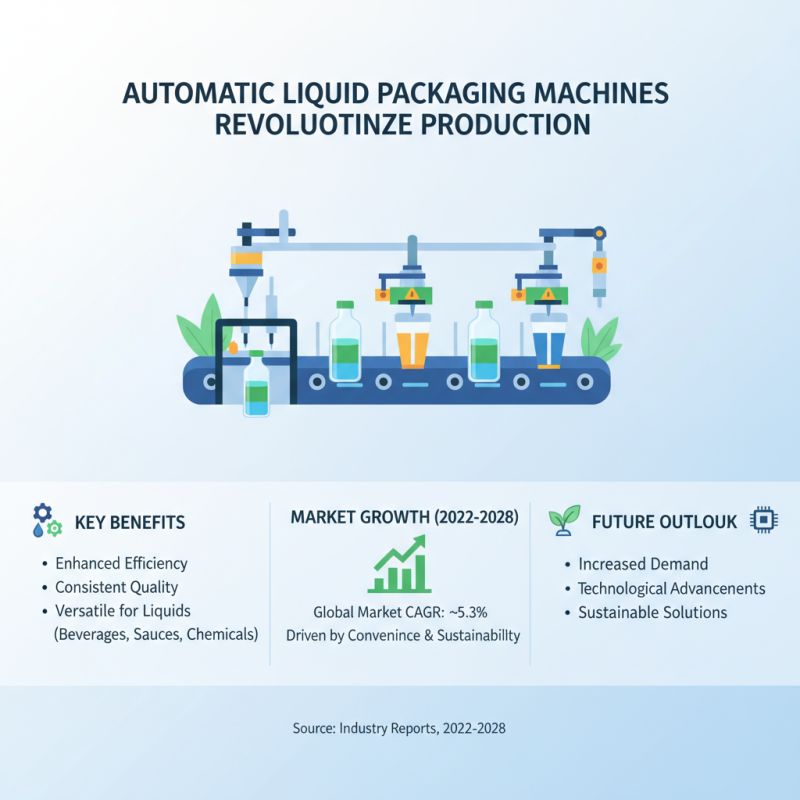

The landscape of automatic liquid packaging technology is rapidly evolving, driven by advancements in efficiency and sustainability. According to a market research report by Grand View Research, the global liquid packaging market is projected to reach $600 billion by 2025, growing at a compound annual growth rate (CAGR) of over 4%. This growth is largely fueled by the demand for convenience and the increasing consumption of liquid products across various sectors, including food and beverage, pharmaceuticals, and personal care.

Top brands in the automatic liquid packaging space are distinguished by their innovative approaches to automation, precision engineering, and robust design. These companies focus on minimizing waste while optimizing production processes to ensure consistent quality and quick turnaround times. A notable trend is the adoption of smart technology, integrating IoT capabilities that allow for real-time monitoring and analytics, which can enhance operational efficiency and reduce downtime.

Tips: When selecting an automatic liquid packaging machine, consider the scalability of the technology. Choosing a machine that can easily adapt to varying production volumes can save significant costs in the long run. Additionally, evaluating the energy efficiency of the packaging solutions can align with sustainability goals while minimizing operational expenses. Implementing preventive maintenance routines can also prolong the life of your equipment, thereby enhancing productivity without the need for frequent replacements.

Comparative Analysis of the Top 10 Liquid Packaging Machines

When evaluating the top liquid packaging machines, several key factors come into play that demonstrate their efficiency and suitability for various production environments. The first aspect is the machine’s speed and output capacity. High-speed automatic machines are designed to accommodate large volumes of liquid products, ensuring that production processes keep pace with market demands. Additionally, the ease of operation and the level of automation significantly influence a machine's desirability. Devices that offer user-friendly interfaces and minimal manual intervention can enhance productivity and reduce labor costs.

Another critical element in the comparative analysis is the versatility of the packaging machine. Many manufacturing facilities require equipment that can handle a range of liquid types, from thin to viscous products. Machines equipped with adjustable nozzles and adaptable filling systems can cater to diverse packaging requirements, making them more cost-effective in the long run. Moreover, considerations regarding hygiene and maintenance play a vital role as well. Automated cleaning systems and robust designs that limit contamination risks are particularly important in industries where product safety is paramount. Evaluating these features helps manufacturers select the most suitable packaging solutions tailored to their operational needs.

Top 10 Automatic Liquid Packaging Machines for Efficient Production

| Machine Model | Production Speed (bottles/min) | Filling Accuracy (%) | Suitable Liquid Types | Dimensions (LxWxH in mm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 200 | 99.5 | Water, Juice | 1500 x 1200 x 1800 | 500 |

| Model B | 180 | 98.0 | Soda, Oil | 1400 x 1100 x 1700 | 450 |

| Model C | 220 | 97.5 | Milk, Juice | 1550 x 1250 x 1850 | 550 |

| Model D | 210 | 99.0 | Sauces, Oils | 1450 x 1150 x 1750 | 530 |

| Model E | 195 | 98.5 | Beverages, Dairies | 1500 x 1200 x 1800 | 480 |

| Model F | 230 | 96.5 | Juice, Wine | 1600 x 1300 x 1900 | 600 |

| Model G | 240 | 100.0 | Creams, Gels | 1650 x 1350 x 1950 | 620 |

| Model H | 205 | 98.8 | Soups, Broths | 1580 x 1280 x 1880 | 540 |

| Model I | 225 | 97.0 | Pickles, Sauces | 1520 x 1220 x 1820 | 580 |

| Model J | 190 | 99.2 | Spirits, Liqueurs | 1470 x 1170 x 1770 | 490 |

Future Trends in Automatic Liquid Packaging Solutions

The landscape of automatic liquid packaging is rapidly evolving, driven by advancements in technology and increasing consumer demand for efficiency and sustainability. A recent industry report from Allied Market Research indicates that the global liquid packaging market is projected to reach $500 billion by 2027, growing at a CAGR of 5.1%. This growth is attributed to the rising consumption of beverages and liquid food products, necessitating more efficient packaging solutions that meet both production speed and environmental standards.

As companies increasingly adopt innovative technologies such as artificial intelligence and IoT, the automation in liquid packaging is becoming smarter and more integrated. Systems equipped with AI can optimize packaging processes in real-time, reducing waste and enhancing accuracy. Moreover, eco-friendly packaging trends are creating a demand for machines that can handle bioplastics and other sustainable materials seamlessly. According to a report by Market Research Future, the segment of sustainable liquid packaging solutions is expected to see a growth rate of over 7% within the next five years, reflecting a significant shift towards environmentally conscious manufacturing practices in the industry.

Thus, the future of automatic liquid packaging is set to focus on maintaining high efficiency while addressing the critical sustainability challenges faced by the industry. As automated systems become increasingly sophisticated and aligned with green initiatives, manufacturers that embrace these trends will likely lead the market in the years to come.

Related Posts

-

How to Choose the Right Liquid Packing Machine for Your Business Needs

-

How to Choose the Best Commercial Peanut Butter Machine for Your Business

-

What is a Peanut Roasting Machine and How Does It Work

-

How to Choose the Best Fish Cutting Machine for Your Kitchen Needs

-

What is a Cane Juice Machine and How Does It Work for Your Business