Top Benefits of Using an Automatic Packaging Machine for Your Business

In today's fast-paced business environment, efficiency and precision are paramount for success. One of the most transformative tools available to modern businesses is the automatic packaging machine. This innovative solution streamlines packaging processes, significantly reducing labor costs and minimizing the risk of human error. By automating the packaging line, companies can enhance productivity, ensure consistent quality, and improve overall operational efficiency.

The benefits of incorporating an automatic packaging machine into your business operations are numerous. Not only do these machines save time and resources, but they also enable businesses to meet increasing consumer demand with agility and reliability. Furthermore, the advanced technology behind automatic packaging machines allows for greater flexibility in packaging designs and materials, catering to various products and market trends. As businesses strive to stay competitive, investing in automatic packaging equipment can be a game-changer, elevating both product presentation and shipping accuracy, while ultimately driving profitability.

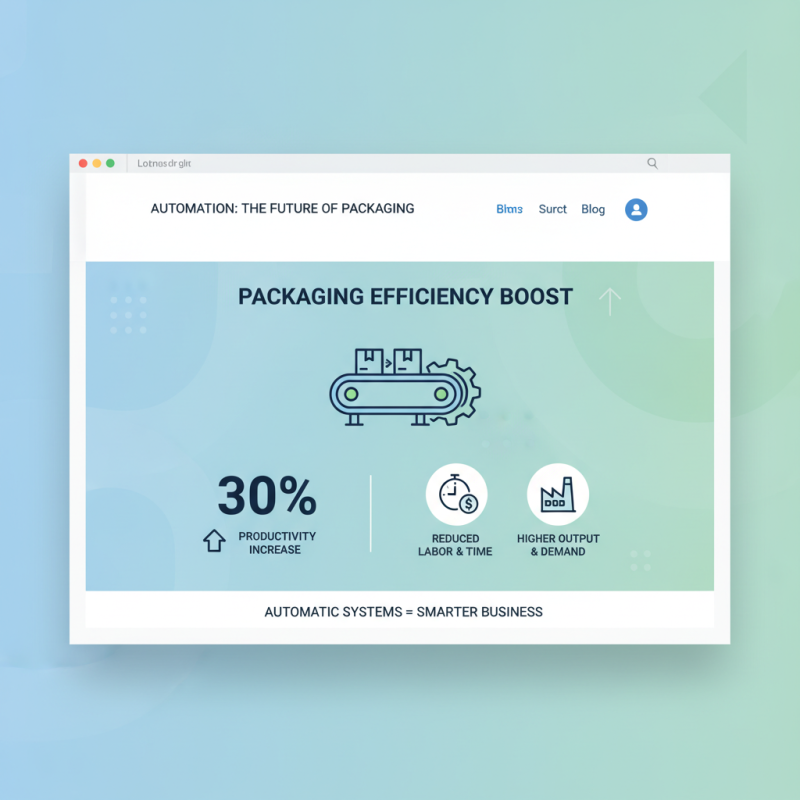

Advantages of Increased Efficiency in Packaging Processes

The efficiency of packaging processes has become a pivotal factor in the overall productivity of businesses across various industries. Automatic packaging machines significantly enhance operational efficiency by minimizing labor costs and reducing packaging time. According to a recent report from the packaging industry, companies that implemented automatic packaging systems observed a productivity increase of up to 30%. This efficiency translates directly into higher output rates, allowing businesses to meet growing consumer demand without sacrificing quality.

In addition to speed, automatic packaging machines often come with advanced technology that ensures precision and consistency, reducing the risk of errors. A study highlighted in the Journal of Packaging Technology indicated that businesses utilizing automated solutions could achieve a reduction in material waste by as much as 25%. This is crucial not only for cost-saving but also for promoting sustainable practices in packaging. The resulting improvements in package integrity and presentation further bolster customer satisfaction and brand loyalty in a competitive marketplace. Overall, the integration of automatic packaging machines into production lines represents an essential step toward maximizing efficiency in packaging processes.

Cost Savings Through Reduced Labor with Automatic Machines

Investing in an automatic packaging machine can lead to significant

cost savings for businesses by minimizing labor expenses. Traditional packaging processes often require a

large workforce, which not only increases payroll costs but also introduces various operational inefficiencies.

Automatic machines streamline the packaging process, allowing businesses to reallocate labor resources

more effectively, minimizing the need for manual intervention. This shift not only reduces direct labor

costs but also lowers the associated expenses of training and employee management.

Moreover, the efficiency of automatic packaging systems contributes to faster production rates,

enabling businesses to meet higher demand without the proportional increase in labor costs. These machines

can operate continuously, reducing downtime and increasing output. The reduction in labor requirements

combined with enhanced efficiency means that companies can achieve higher profit margins

while maintaining competitive pricing. Additionally, with less labor reliance, companies can also mitigate

risks associated with workforce fluctuations, such as absenteeism or turnover, further stabilizing operational

costs and enhancing overall profitability.

Enhanced Product Consistency and Quality Control

The integration of automatic packaging machines into business operations offers significant advantages, particularly in enhancing product consistency and quality control. According to a report by PMMI, the Association for Packaging and Processing Technologies, nearly 70% of manufacturers have observed improved product quality as a direct result of automated packaging solutions. These machines minimize human error, ensuring that each package meets stringent specifications, which is crucial in maintaining brand integrity and customer satisfaction.

Moreover, automatic packaging machines maintain uniformity in packaging dimensions, sealing strengths, and labeling accuracy. Research indicates that companies employing automated systems can reduce packaging defects by over 30%, thus improving overall efficiency. As a result, organizations not only lower their waste rates but also enhance their ability to meet consumer demand with consistent product presentations.

The emphasis on quality control has become increasingly vital in competitive markets, where any variation can diminish customer trust and lead to loss of sales. Enhanced precision in the packaging process ensures that products not only look appealing but also remain sealed and protected, preserving their quality throughout the supply chain.

Scalability: Meeting Growing Demands with Automation

In today’s fast-paced market, scalability is a critical component for businesses aiming to expand and meet the increasing demands of their customers.

Automatic packaging machines significantly enhance a company’s capacity to scale operations efficiently. According to a report by Smithers Pira, the global demand for automated packaging systems is expected to grow at a CAGR of 14% from 2020 to 2025. This surge underscores the necessity for businesses to adopt automation to keep up with evolving consumer patterns.

Implementing automatic packaging solutions not only increases throughput but also reduces labor costs and minimizes human errors. Industry experts estimate that businesses can achieve a 30-50% improvement in productivity within the first year of using automated systems. By streamlining packaging processes, companies can quickly adapt to larger production runs or seasonal spikes in demand without compromising quality or speed.

Tip: When investing in an automatic packaging machine, ensure it can handle different product sizes and types to maximize your scalability.

Furthermore, automation allows for real-time data tracking and analytics. This insight enables businesses to make informed decisions about production adjustments and inventory management — key factors in meeting customer demand promptly. With the ability to quickly reconfigure packaging lines, businesses can respond rapidly to market shifts, ensuring they are always one step ahead of their competitors.

Tip: Regularly review your operational goals and align them with your packaging machine capabilities to ensure they meet both current and future production needs.

Improved Safety and Ergonomics in the Workplace

The implementation of automatic packaging machines in a business setting significantly enhances workplace safety and ergonomics. By automating repetitive tasks, these machines reduce the physical strain on workers, minimizing the risk of injuries associated with manual handling and packaging. This shift not only protects employees from potential accidents but also increases their overall job satisfaction, as they can focus on more skilled tasks that require cognitive input rather than repetitive motions.

Moreover, automatic packaging machines contribute to a safer work environment by decreasing the likelihood of accidents caused by human error. With precise mechanisms in place, these machines ensure consistent packaging quality and speed, thus reducing the chaos often seen in manual operations. As a result, workers can operate in a more organized space where hazards are minimized. Enhanced safety protocols ultimately lead to a more productive workforce, as employees can perform their duties with greater confidence, knowing their environment is equipped with equipment designed to prioritize their well-being.

Top Benefits of Using an Automatic Packaging Machine for Your Business

This chart illustrates the key benefits of using automatic packaging machines in a business context, showcasing improvements in safety, efficiency, cost savings, ergonomics, and product quality.

Related Posts

-

Top 10 Automatic Liquid Packaging Machines for Efficient Production

-

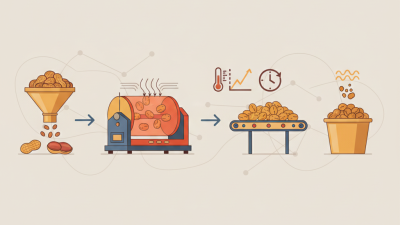

What is a Peanut Roasting Machine and How Does It Work

-

How to Choose the Best Commercial Peanut Butter Machine for Your Business

-

How to Choose the Right Liquid Packing Machine for Your Business Needs

-

What is a Cane Juice Machine and How Does It Work for Your Business

-

How to Choose the Best Fish Cutting Machine for Your Kitchen Needs