What is a Cane Juice Machine and How Does It Work for Your Business

The cane juice machine plays a pivotal role in the booming beverage industry, offering an efficient solution for extracting fresh sugarcane juice. Recent industry reports indicate that the global cane juice market is experiencing significant growth, with projections suggesting a compound annual growth rate (CAGR) of over 5% from 2023 to 2028. This growth is spurred by increasing consumer demand for natural and health-oriented beverages, as well as the expanding trend of juice bars and health cafes in urban areas.

Businesses looking to capitalize on this trend can greatly benefit from investing in a high-quality cane juice machine. Not only does it ensure the efficient extraction of juice, but it also enhances product quality and freshness, which are critical factors influencing consumer purchasing decisions. According to the Beverage Marketing Corporation, freshly pressed juices can command a premium price point in the market, which can significantly boost profit margins for businesses that adopt this technology. As the preferences for natural products continue to rise, implementing a cane juice machine becomes a strategic move for any business aiming to thrive in the competitive beverage landscape.

What is a Cane Juice Machine?

A cane juice machine is a specialized device designed to extract juice from sugarcane, providing a fresh and nutritious beverage that has gained popularity in various markets worldwide. Typically used in juice bars, restaurants, and street vendors, these machines facilitate the efficient production of cane juice, which is not only delicious but also rich in essential nutrients. According to industry reports, the global sugarcane juice market is projected to witness significant growth, driven by the rising consumer preference for natural and healthy beverages.

The operation of a cane juice machine involves several key components that work together to optimize juice extraction. The primary process begins with feeding whole sugarcane into the machine, which then utilizes rollers to crush the cane and release the juice. Many modern machines are equipped with advanced technology to ensure maximum efficiency, with some capable of extracting up to 95% of the juice from the cane. The juice produced is often enjoyed fresh, retaining its natural sweetness and nutritional benefits, which include vitamins, minerals, and antioxidants. Research indicates that sugarcane juice can boost energy levels and support hydration, making it an attractive option for health-conscious consumers.

Furthermore, the financial viability of investing in a cane juice machine can be highlighted by the growing demand for fresh juice products. Data shows that the global market for natural juice products is on an upward trajectory, with consumers increasingly seeking out fresh and organic options. Implementing a cane juice machine can help businesses tap into this lucrative market, offering a unique product that stands out among traditional beverage offerings. With proper marketing and a focus on quality, businesses can capitalize on the trend towards healthier lifestyles and sustainable sourcing.

Key Components of a Cane Juice Machine

A cane juice machine is a specialized device designed to extract juice from sugarcane, making it an essential tool for businesses in the beverage industry. Understanding its key components can help owners optimize their operations and enhance the quality of the juice produced. The primary components of a cane juice machine include rollers, a feeding mechanism, and a collection system.

The rollers are crucial for the extraction process, as they apply pressure to the sugarcane stalks, breaking down the fibrous material and releasing the juice. These rollers are typically made of durable materials to withstand the tough nature of sugarcane. The feeding mechanism ensures that the cane is fed smoothly and consistently into the rollers, minimizing downtime and maximizing efficiency. Finally, the collection system gathers the extracted juice, channeling it into containers or storage tanks for further processing or sale. By understanding these components, businesses can better appreciate the functionality of a cane juice machine and how it can streamline their operations.

Additionally, many modern cane juice machines also incorporate features such as adjustable roller spacing and automatic cleaning systems, which further enhance usability and maintenance. These innovations allow businesses to cater to varying production needs while ensuring that the equipment remains in optimal working condition over time. By investing in a reliable cane juice machine with well-designed components, businesses can improve their product offerings and meet customer demands effectively.

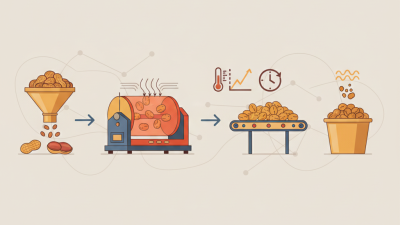

How Cane Juice Machines Operate: Step-by-Step Process

Cane juice machines are specialized devices designed to extract juice from sugar cane, a process that can be pivotal for businesses in the beverage industry. The operation of these machines is straightforward yet efficient, starting with the preparation of the sugar cane itself. First, fresh sugar cane stalks are thoroughly washed to remove any dirt or impurities. This ensures that the extracted juice is clean and safe for consumption. After washing, the cane is cut into manageable pieces, making it easier for the machine to process.

Once the cane is prepared, it is fed into the machine where mechanical rollers crush the stalks. This step is crucial as it applies significant pressure to extract the juice effectively. The juice flows through a designated outlet, while the fibrous residue, known as bagasse, is expelled separately. Many cane juice machines are equipped with multiple rollers to maximize extraction efficiency, ensuring that as much juice as possible is obtained from each stalk. The final step involves filtering the extracted juice to remove any remaining solids, resulting in a smooth and refreshing product ready for consumption or further processing for beverages.

What is a Cane Juice Machine and How Does It Work for Your Business - How Cane Juice Machines Operate: Step-by-Step Process

| Step | Description | Time Required | Key Benefits |

|---|---|---|---|

| 1 | Feeding the Sugarcane | 5 minutes | Fresh cane juice extraction starts immediately. |

| 2 | Washing the Sugarcane | 2 minutes | Ensures hygiene and removes dirt for better quality juice. |

| 3 | Crushing Process | 10 minutes | Maximum juice extraction with minimal waste. |

| 4 | Juice Filtration | 3 minutes | Removes impurities for a clear and pure product. |

| 5 | Storing the Juice | Variable | Preserves the freshness and flavor until served. |

| 6 | Serving the Juice | Instant | Ready to serve to customers for immediate consumption. |

| 7 | Cleaning the Machine | 5 minutes | Ensures longevity of the machine and maintains hygiene. |

Benefits of Using a Cane Juice Machine for Your Business

Cane juice machines have become increasingly popular in the beverage industry, especially for businesses looking to provide fresh and nutritious drink options. One of the major benefits of using a cane juice machine is the ability to produce high-quality, fresh sugarcane juice on-site. According to industry reports, the global sugarcane juice market is projected to grow at a CAGR of 8.5% from 2021 to 2026, indicating a rising consumer preference for natural and freshly extracted beverages. By investing in a cane juice machine, businesses can tap into this growing market and attract health-conscious consumers who are seeking refreshing alternatives to sugary sodas.

In addition to meeting market demand, cane juice machines offer several operational advantages. These machines are designed to extract juice efficiently while maintaining the natural flavors and nutritional benefits of sugarcane. Studies have shown that freshly pressed cane juice retains essential vitamins and minerals, such as calcium, magnesium, and potassium, which can enhance the health profile of a business’s beverage offerings. Furthermore, using a cane juice machine reduces the need for preservatives and artificial additives, appealing to the increasing number of consumers who prioritize clean-label products. By providing a fresh, nutritious, and environmentally friendly option, businesses can differentiate themselves in a competitive market, ultimately leading to increased customer loyalty and sales growth.

Choosing the Right Cane Juice Machine for Your Needs

When selecting the right cane juice machine for your business, it's vital to consider various factors that align with your operational needs and target market. According to industry reports, the demand for fresh sugarcane juice has seen a significant rise, particularly in tropical and subtropical regions, driven by consumer preferences for natural beverages. A high-quality cane juice machine can enhance productivity and preserve the nutritional value of the juice, which is crucial for customer satisfaction and repeat business.

Key specifications to focus on include extraction efficiency, ease of use, and maintenance requirements. A machine with a higher extraction rate can maximize your yield, which is an essential aspect of profitability. Reports from the Beverage Industry Association indicate that machines capable of extracting over 95% of the juice from cane significantly reduce waste and improve revenue margins. Moreover, opting for user-friendly equipment can minimize training time for staff, ensuring that your operations run smoothly and efficiently from day one. Understanding your volume needs, whether for a small juice stand or a larger operation, will further guide your choice, allowing you to invest in a machine that supports growth while meeting market demand.