How to Choose the Right Liquid Packing Machine for Your Business Needs

When it comes to scaling up production in industries that handle liquids, selecting the right liquid packing machine is a pivotal decision for any business. The market offers a variety of options, each designed to cater to specific product types, production volumes, and operational requirements. Understanding your business needs is essential in making an informed choice, which can enhance efficiency, reduce waste, and ultimately lead to increased profitability.

A liquid packing machine must align with the unique characteristics of the product being packaged, whether it be viscosity, temperature, or sensitivity to light and air. Additionally, considerations such as automation level, ease of maintenance, and compatibility with existing systems play crucial roles in determining the best fit for your operations. By carefully assessing these factors, businesses can ensure they invest in a liquid packing machine that not only meets current needs but also accommodates future growth and adaptations.

In this guide, we will delve into the essential criteria for selecting a liquid packing machine tailored to your business requirements. From understanding the different types of machines available to evaluating throughput capabilities and integration options, making the right choice can streamline your packaging process and enhance overall operational success.

Understanding Your Liquid Packaging Requirements

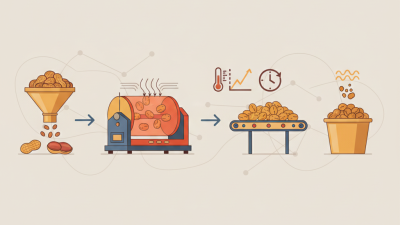

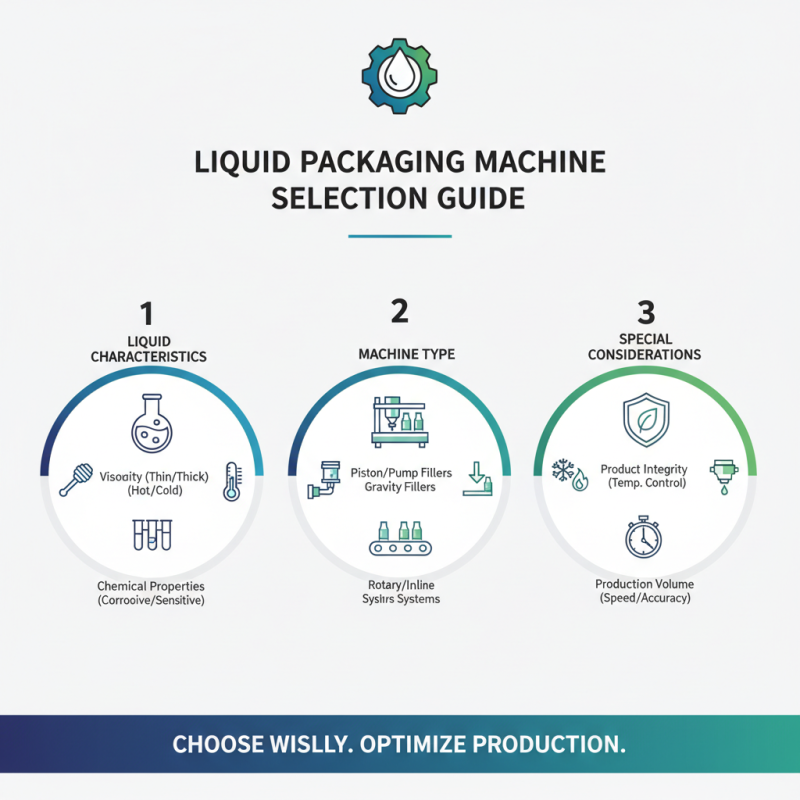

When selecting the right liquid packing machine, understanding your liquid packaging requirements is paramount. Start by assessing the characteristics of the liquids you need to package. Consider factors such as viscosity, temperature, and chemical properties, as these will significantly influence the type of machine you need. For instance, thicker liquids may require more robust mechanisms to ensure efficient filling without spills, while temperature-sensitive products may need machines equipped with temperature control features to maintain product integrity.

Next, evaluate the packaging formats that align with your business needs. Whether you aim for bottles, pouches, or cartons, knowing the desired final packaging format can help narrow down your choices. Additionally, consider the production speed and volume required for your operation. A high-throughput environment may necessitate an automatic liquid filling machine that can maintain efficiency, while smaller operations might benefit from semi-automatic systems that are more cost-effective and versatile. By aligning the machine’s capabilities with your specific packaging requirements, you can enhance productivity and ensure the quality of your packaged products.

Types of Liquid Packing Machines Available

When selecting a liquid packing machine, understanding the different types available is crucial for meeting your business needs. The most common types include vertical form-fill-seal (VFFS) machines, horizontal form-fill-seal (HFFS) machines, and single-use pouch filling machines. VFFS machines are particularly popular in the food and beverage industry due to their efficiency in packaging liquids like juices and sauces. According to a market research report by Grand View Research, the VFFS segment is expected to grow significantly, driven by the rising demand for ready-to-eat meals and on-the-go beverages.

HFFS machines, on the other hand, are revered for their versatility and ability to handle various container types, such as pouches, bottles, and cartons. These machines are ideal for businesses looking to package products that require high-speed operations and precise filling capabilities, such as dairy products and cleaning liquids. Furthermore, data from Research and Markets indicates that the horizontal packaging machinery market is projected to witness substantial growth, with an anticipated CAGR of over 4% from 2022 to 2030, reflecting the increasing automation in packing processes across various industries.

Lastly, single-use pouch filling machines offer an innovative solution for businesses focusing on portion control and convenience. These machines are gaining traction in sectors like personal care and pharmaceuticals, where hygiene and tamper-proof solutions are paramount. As the trend toward eco-friendly and sustainable packaging continues to rise, single-use pouch machines are becoming integral in reducing waste and resource utilization, appealing to environmentally conscious consumers. Investing in the right type of liquid packing machine can enhance operational efficiency and position businesses competitively in a rapidly evolving market.

Key Features to Consider in a Liquid Packing Machine

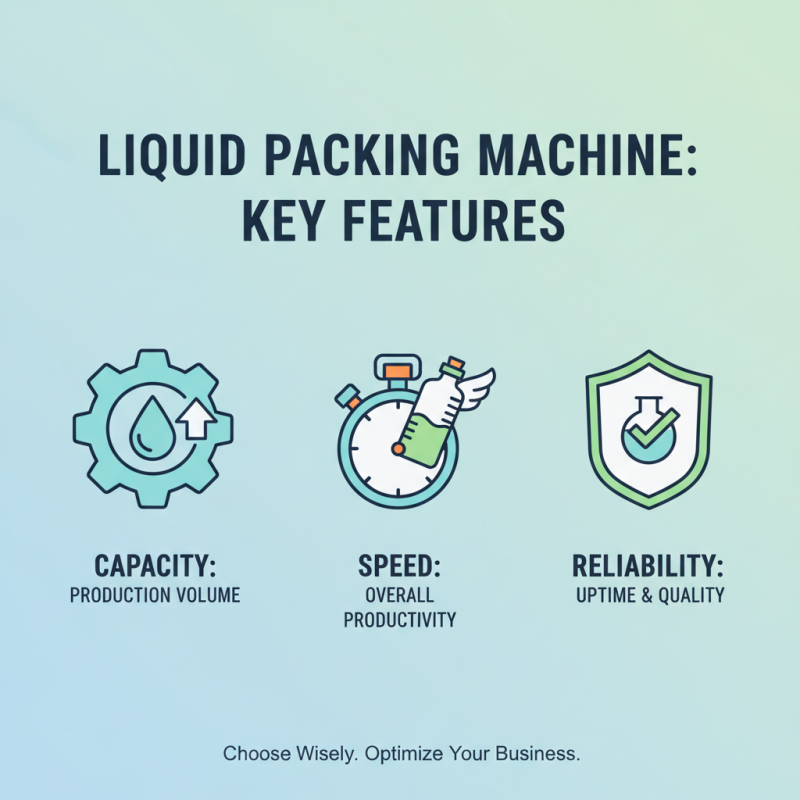

When choosing a liquid packing machine for your business, several key features should be considered to ensure that the machine meets your specific needs. First and foremost, the machine’s capacity is critical. You need to assess your production volume and select a machine that can handle your requirements efficiently without causing bottlenecks. Additionally, examine the speed of the machine, as this will influence your overall productivity.

Another essential feature to consider is the type of liquid being packed. Different liquids have varying viscosities and characteristics; therefore, ensure the machine is compatible with the type of liquid you’re handling. Whether you’re dealing with water-thin liquids, thick sauces, or sensitive pharmaceuticals, your equipment must be tailored to accommodate these differences.

**Tips:** Always ask for machine demonstrations whenever possible. This will provide insights into the machine’s functionality and adaptability to your particular liquids. Furthermore, consider the ease of maintenance and the availability of replacement parts, as this will affect the long-term operational efficiency of your packing line. By focusing on these crucial features, you can make an informed decision that aligns with your business objectives.

Evaluating Manufacturer Reputation and Support

When choosing a liquid packing machine for your business, evaluating the manufacturer's reputation and the level of support they provide is crucial. Research shows that nearly 70% of businesses prioritize these factors due to their significant impact on operational efficiency and product quality. A reliable manufacturer not only offers top-notch machinery but also ensures that their customers have access to installation guidance, maintenance services, and prompt responses to queries. According to a recent market analysis by Smithers Pira, brands with strong customer service and technical support have seen a 15% increase in customer satisfaction, which directly influences repeat business and word-of-mouth referrals.

**Tip:** Before making a purchase, assess the manufacturer’s history in the industry. Look for reviews or case studies that demonstrate their commitment to quality and support. Engaging with existing customers can provide valuable insights into their experiences, especially concerning after-sales service.

Additionally, consider the training and resources the manufacturer provides. A comprehensive training program can lead to more effective operation of the machinery, reducing downtime and enhancing productivity. As evidenced by a report from Packaging Strategies, companies that invest in training see a 20% increase in operational efficiency within the first year of implementation.

**Tip:** Inquire about the availability of training materials, online resources, and customer support services. Having a knowledgeable support team can ease the transition to new machinery and ensure your business runs smoothly.

How to Choose the Right Liquid Packing Machine for Your Business Needs

| Feature | Importance | Considerations |

|---|---|---|

| Machine Capacity | High | Match capacity with production volume needs |

| Type of Liquid | Critical | Viscosity and pH can affect selection |

| Automation Level | Medium | Consider labor costs vs. investment in technology |

| Ease of Maintenance | High | Schedule downtime for maintenance |

| Manufacturer Support | High | Quality of customer service and parts availability |

| Cost | High | Balance initial cost vs. long-term savings |

| Flexibility | Medium | Ability to adjust for different products and sizes |

Budgeting for Your Liquid Packing Machine Investment

When budgeting for a liquid packing machine, it is essential to consider not only the initial purchase price but also ongoing operational costs. These costs can include maintenance, labor, and utilities associated with running the machine. A well-planned budget will help ensure that your investment aligns with your financial goals and operational needs.

Tips: Start by evaluating your production volume and required speed to select a machine that fits both your current and future needs. This foresight can save you money down the line by avoiding premature upgrades or replacements. Additionally, consider the machine’s efficiency; investing in energy-efficient equipment can lead to substantial savings on utility costs over time.

It's also wise to account for potential hidden costs. Shipping and installation can add to the overall expense, while training for employees who will operate the machine is an essential factor that can influence both productivity and safety. Always ensure your budget includes these elements to avoid unexpected financial strain during implementation. Keep in mind the total cost of ownership, which goes beyond just the purchase price and includes all these factors.

Liquid Packing Machine Investment Breakdown

This chart illustrates the various investment costs associated with acquiring a liquid packing machine for your business, including initial costs, maintenance, training, operational expenses, and potential savings. Understanding these components can help optimize budgeting for your liquid packing machine investment.