How to Choose the Best Commercial Peanut Butter Machine for Your Business

When it comes to running a successful food business, selecting the right equipment is crucial. One of the essential machines that can significantly enhance your production efficiency is a commercial peanut butter machine. This specialized piece of equipment not only allows for the seamless processing of peanuts into smooth and creamy butter but also offers a range of customization options to suit different business needs. With various models and features available on the market, it can be overwhelming to determine which commercial peanut butter machine is the best fit for your operation.

In this guide, we will explore key considerations to keep in mind when choosing the ideal commercial peanut butter machine for your business. Factors such as production capacity, ease of use, maintenance requirements, and overall cost-effectiveness will be examined. By understanding these aspects, you can make an informed decision that not only meets your production demands but also aligns with your business goals. Whether you are starting a new venture or looking to upgrade your existing equipment, finding the right commercial peanut butter machine is essential for maximizing your output and ensuring high-quality products.

Understanding Your Business Needs for Peanut Butter Production

When selecting a commercial peanut butter machine, understanding your business needs is paramount. According to a recent industry report from Market Research Future, the peanut butter market is expected to grow at a CAGR of 7.3% from 2021 to 2026, indicating a rising demand for peanut butter products. This growth emphasizes the importance of choosing a machine that aligns not only with production capacity but also with the specific type of peanut butter your business aims to produce. For instance, a machine with adjustable grinding settings will allow you to create various textures, catering to both creamy and crunchy preferences popular among consumers today.

Additionally, considering the volume of peanut butter you intend to produce is critical. A small artisanal business may require a machine with a lower output capacity, while a larger commercial operation will benefit from high-capacity machines that can handle thousands of pounds of peanuts per hour. According to research by IBISWorld, the peanut butter production industry is largely characterized by its high level of automation. Therefore, investing in advanced machinery with automated features not only improves efficiency but also reduces labor costs while maintaining consistent quality in production. By carefully analyzing your business needs, including production scale and desired product characteristics, you can choose the best commercial peanut butter machine that will drive your business forward.

Types of Commercial Peanut Butter Machines and Their Features

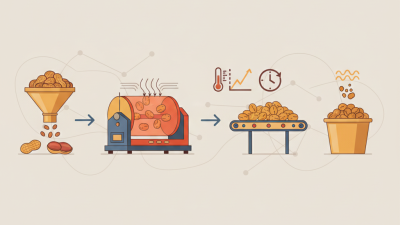

When selecting a commercial peanut butter machine, it is important to understand the various types available and their unique features. The most common type is the stone mill machine, which utilizes traditional methods to grind peanuts into a smooth paste. This type often retains more of the natural oils and flavor, which many consumers appreciate. However, stone mills can be slower and may have lower production capacity, making them more suitable for small-scale operations.

Another popular option is the stainless steel colloid mill, known for its efficiency and ability to handle larger volumes. These machines employ a high-speed rotor to create a fine texture, resulting in a smooth and consistent product. Colloid mills are easier to clean and maintain, making them ideal for businesses that prioritize hygiene. Additionally, some models come with adjustable settings to customize the texture and consistency of peanut butter, enhancing flexibility in production to meet specific customer preferences. Understanding these types and their features can significantly impact the success of your peanut butter business.

Commercial Peanut Butter Machine Features Comparison

Key Factors to Consider When Choosing a Peanut Butter Machine

When selecting a commercial peanut butter machine, several key factors must be considered to ensure optimal performance and efficiency for your business. First, capacity is paramount. A medium-sized operation may require a machine that can produce anywhere from 20 to 100 pounds of peanut butter per hour. According to industry reports, demand for nut-based spreads has seen a steady increase, with an expected growth rate of 6.5% annually through 2027, making the choice of a reliable production capacity crucial for meeting market needs.

Another critical factor is the machine's grinding technology. The effectiveness of the grinding mechanism directly affects the texture and consistency of the peanut butter. Machines that utilize a steel grinding system are typically favored for their durability and ability to produce a creamy end product. Furthermore, energy efficiency is increasingly important; modern machines are designed to minimize energy consumption, with some models boasting reductions of up to 30% compared to older versions. This not only lowers operational costs but also appeals to environmentally conscious consumers, making it a vital consideration for businesses aiming to enhance their sustainability profile.

Evaluating Cost vs. Quality in Peanut Butter Machinery

When evaluating the cost vs. quality in peanut butter machinery, it’s essential for businesses to determine which factors will best suit their production needs while remaining within budget. The global peanut butter machine market is projected to reach $1.2 billion by 2027, according to industry analysis, emphasizing the growing demand for efficient and high-quality equipment. Investing in a high-quality machine may incur higher initial costs, but it can significantly reduce maintenance expenses and enhance production consistency. For instance, a robust grinding mechanism, typically found in higher-end machines, can ensure that the peanut butter produced maintains a uniform texture, which is critical for customer satisfaction and repeat purchases.

Moreover, it's vital to consider the long-term operational costs associated with different machines. A study revealed that machines with more advanced technology may demonstrate lower energy consumption rates, translating to operational savings over time. For instance, machines that utilize variable frequency drives can lead to energy costs saving of up to 30%. Additionally, businesses should assess the durability and warranty offered by manufacturers, as this can be a telling sign of a machine's quality. Ultimately, balancing upfront costs with potential future savings and product quality is crucial in the decision-making process for any business looking to invest in peanut butter production equipment.

Maintenance and Support Considerations for Peanut Butter Machines

When selecting a commercial peanut butter machine, maintenance and support considerations play a crucial role in ensuring the longevity and efficiency of your equipment. According to industry data, approximately 30% of machine failures can be attributed to poor maintenance practices. Therefore, it is essential to choose a machine backed by comprehensive support services, including readily available spare parts and accessible technical assistance. Regular maintenance schedules, along with proper training for your staff, can help mitigate downtime and optimize overall performance.

Another critical consideration is the warranty and service agreements offered by manufacturers. Data from the Food Processing Equipment Manufacturing Association indicates that businesses investing in equipment with strong service support experience a 20% reduction in operational costs over time. This is largely due to reduced repair expenses and extended equipment life. Ensuring that the supplier provides a robust maintenance program not only enhances machine reliability but also builds confidence in the equipment's performance, leading to increased productivity and profitability for your peanut butter production business.

How to Choose the Best Commercial Peanut Butter Machine for Your Business - Maintenance and Support Considerations for Peanut Butter Machines

| Feature | Importance | Maintenance Frequency | Support Type |

|---|---|---|---|

| Motor Power | High | Weekly Check | 24/7 Phone Support |

| Blade Quality | Medium | Monthly Inspection | Email Support |

| Ease of Cleaning | High | After Each Use | On-Site Training |

| Warranty Length | Medium | N/A | Limited Warranty Support |

| Energy Efficiency | High | Yearly Review | Online Resources |