How to Choose the Best Fish Cutting Machine for Your Kitchen Needs

Choosing the right fish cutting machine for your kitchen is crucial for both home cooks and professional chefs. Renowned culinary expert Chef Mark Thompson emphasizes, "A quality fish cutting machine not only enhances efficiency but also ensures the precision and quality of your cuts, which is essential for any seafood dish." With the rise of home cooking and the increasing popularity of seafood dishes, selecting the best fish cutting machine has become more important than ever.

When considering a fish cutting machine, factors such as blade quality, size, and ease of use should be taken into account. A high-performance machine can make the difference between a perfectly filleted fish and a frustrating experience. Furthermore, the features and capabilities of these machines can greatly impact the preparation time and the overall presentation of your dishes.

In this guide, we will explore the key aspects to look for in a fish cutting machine, helping you make an informed decision to elevate your culinary skills and create delightful seafood masterpieces in your kitchen.

Factors to Consider When Selecting a Fish Cutting Machine for Home Use

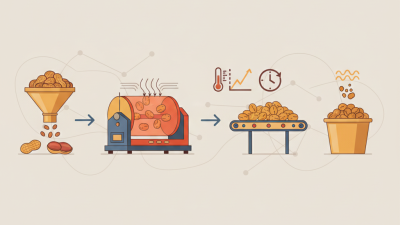

When selecting a fish cutting machine for home use, there are several key factors to consider to ensure you make the right choice for your kitchen needs. First and foremost, consider the machine's size and capacity. If you have limited counter space or if you're a casual home cook, a compact model may be more suitable. Conversely, if you frequently prepare large quantities of fish or engage in meal prepping, a larger machine with a higher capacity will save you time and effort.

Another important aspect is the material and build quality of the fish cutting machine. Look for machines made from durable, rust-resistant materials such as stainless steel, which can withstand regular use and are easy to clean. Additionally, pay attention to the blade quality; sharp and high-quality blades will not only improve cutting efficiency but also enhance safety. Finally, consider the ease of operation and maintenance of the machine. User-friendly features, such as adjustable thickness settings and easy disassembly for thorough cleaning, can greatly enhance your cooking experience and ensure the longevity of the machine.

Types of Fish Cutting Machines: Understanding Your Options and Features

When selecting the best fish cutting machine for your kitchen, understanding the various types and features available is crucial. There are primarily three categories of fish cutting machines: manual, semi-automatic, and fully automatic. Manual machines are suited for smaller operations or home kitchens, requiring physical effort but providing excellent control over cuts. According to industry reports, this type of machine is popular among chefs who prefer a hands-on approach for precision tasks.

On the other hand, semi-automatic machines combine manual labor with mechanized assistance, facilitating higher efficiency without sacrificing quality. They typically feature adjustable cutting speeds and varying thickness settings to accommodate different fish types. The Global Fish Processing Equipment Market Report highlights that demand for semi-automatic machines has surged by approximately 28% in recent years, indicating a trend towards augmentation in traditional methods. Fully automatic machines represent the latest technology, capable of handling large volumes with minimal human intervention. These machines often integrate advanced features such as programmable cut options and automated cleaning systems, making them ideal for commercial kitchens with high turnover rates.

When choosing a fish cutting machine, consider factors such as cutting capacity, ease of cleaning, and the specific types of fish you intend to prepare. Research suggests that investing in a well-suited machine can substantially enhance workflow efficiency and the overall quality of fish preparation, ultimately leading to a better culinary experience.

Key Specifications and Performance Metrics for Fish Cutting Machines

When selecting a fish cutting machine, understanding the key specifications and performance metrics is crucial to ensure it meets your kitchen needs. First, consider the blade type and material. Stainless steel blades are preferable for their durability and resistance to corrosion. The sharpness and design of the blade also impact the cutting efficiency; a well-designed blade can provide cleaner cuts, essential for maintaining the quality of fish fillets.

Another critical metric is the machine's cutting capacity, often reflected in the weight of fish it can handle per hour. This specification is particularly important for commercial kitchens or high-volume operations. Additionally, evaluate the machine's speed settings. Adjustable speeds can offer versatility in cutting different types and sizes of fish, ensuring a precise approach for various culinary applications. Pay attention to safety features as well, such as guards and automatic shut-off systems, to prevent accidents during operation, making the fish cutting process both safe and efficient.

Performance Metrics of Fish Cutting Machines

Maintenance and Safety Tips for Optimal Fish Cutting Machine Operation

When it comes to operating a fish cutting machine, maintaining safety and ensuring optimal performance are paramount. A well-maintained machine not only enhances efficiency but also reduces the risk of accidents in the kitchen. Regularly check the machine for any worn-out parts, as these can result in dangerous malfunctions. Keeping the blades sharp and cleaning the machine after each use not only maintains hygiene but also prolongs its lifespan.

When you need to change blades, always disconnect the machine from the power source to prevent accidental startups. Utilizing proper technique, such as maintaining a steady grip and avoiding overreaching, will further ensure a safe cutting process.

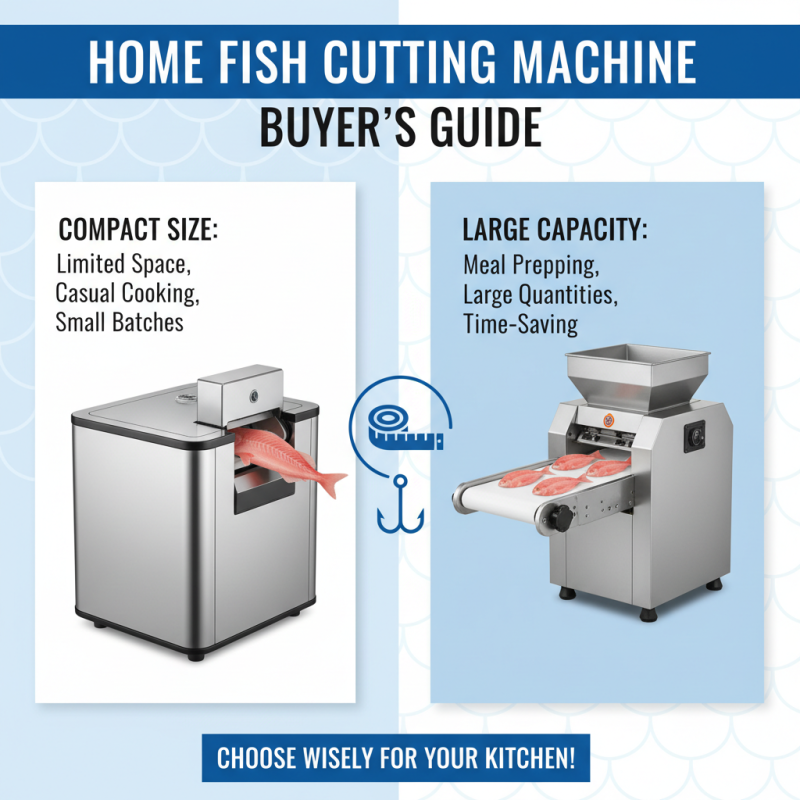

Comparative Analysis of Leading Fish Cutting Machine Brands and Models

When selecting a fish cutting machine for your kitchen, a comparative analysis of leading brands and models is crucial to ensure you meet your culinary needs effectively. Recent industry reports indicate that the global fish processing equipment market is projected to grow at a CAGR of 5.4% from 2022 to 2030, reflecting an increasing demand for efficient processing tools in both commercial and residential settings. The key differentiators among models usually include cutting speed, blade quality, and ease of cleaning.

Top-tier models often feature stainless steel blades designed for durability and precision, with cutting speeds varying significantly from one brand to another. Studies show that machines capable of processing 200 kg of fish per hour are considered optimal for medium to high-volume kitchens, making it vital to assess your specific throughput requirements. Additionally, ease of operation and maintenance should not be overlooked; many leading models offer ergonomic designs and automatic cleaning systems, which can greatly enhance user experience. By prioritizing these aspects, you can ensure you select a fish cutting machine that not only meets your current needs but also facilitates future culinary pursuits.