Top Features of Sauce Packing Machines in the Food Industry?

The food industry is evolving rapidly, with the demand for sauce packing machines on the rise. According to a recent market report, the global sauce packaging market is expected to grow at a CAGR of 4.4% by 2026. This growth reflects a robust consumer preference for convenience and ready-to-use sauces.

Modern sauce packing machines are designed to enhance efficiency and maintain quality. These machines allow for precise filling, ensuring that every package meets food safety standards. Recent studies indicate that automation in packaging can increase production rates by up to 30%. However, not all manufacturers have adopted these innovations.

Investing in advanced sauce packing machines can be costly. Smaller businesses may struggle to keep up. The equipment needs to be reliable yet adaptable to varying product lines. These challenges need addressing as the demand for sauces continues to rise. Ensuring the right technology is employed is vital for success in this competitive market.

Key Technologies in Sauce Packing Machines

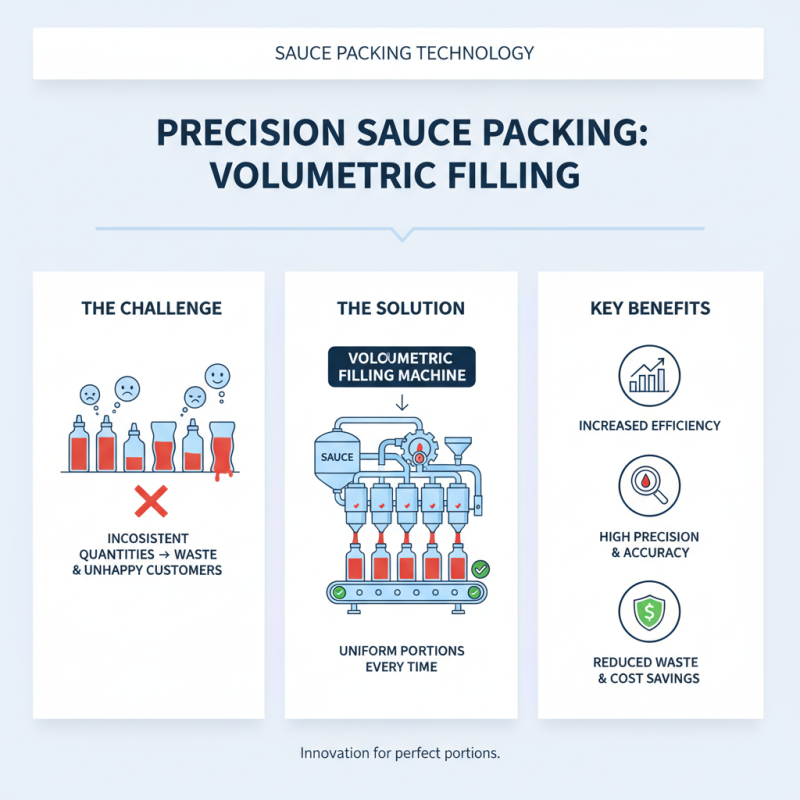

In the realm of food packaging, sauce packing machines play a crucial role. These machines utilize cutting-edge technologies to improve efficiency and precision. One key technology is volumetric filling, which ensures uniform quantities in every bottle or pouch. This technique minimizes inconsistencies that can lead to waste or dissatisfied customers.

Another significant advancement is the integration of sensors. These sensors monitor the filling process in real-time, allowing for immediate adjustments. This feature helps prevent overfilling or underfilling, which can be costly. Additionally, some machines utilize electromagnetic induction sealing. This sealing method extends shelf life by securely sealing containers without contaminants.

Yet, not all machines are created equal. Some might struggle with varying sauce viscosities, leading to inconsistent fills. Regular maintenance and calibration are crucial to mitigate these issues. Operators must also be trained to handle diverse packaging formats. The technology is impressive, but continuous improvement is always needed in the fast-evolving food industry.

Types of Sauce Packing Machines Utilized in the Food Industry

In the food industry, sauce packing machines come in various types. Each type serves a unique purpose. For example, piston fillers are popular for their precision. They handle thick sauces well, ensuring accurate fill levels. This capability is crucial for consistent taste and quality.

Another type is the volumetric filler. These machines are great for a range of viscosities. They can pack everything from ketchup to marinades. Adjusting for different sauce types is straightforward. However, calibration may require some testing to maintain accuracy.

In addition, we have gravity fillers, best suited for thin liquids. They rely on gravity for filling, which might lead to inconsistency. Operator training is essential to minimize errors. Ultimately, each machine plays a vital role in sauce packing. Choosing the right type can enhance production efficiency. Yet, it’s essential to consider the specific needs of the product being packed.

Automation and Efficiency Features of Modern Packing Equipment

In the food industry, automation is transforming the sauce packing process. Modern packing machines streamline operations. They reduce manual labor and improve speed. This leads to increased output and reduced human error. The precision of these machines ensures consistent filling, which is crucial for product quality.

Tip 1: Regular maintenance checks can prevent unexpected downtime. A well-maintained machine runs smoothly.

While automation boosts efficiency, it can also bring challenges. Employees may need retraining to adapt. Understanding the technology is vital for optimal use. Embracing change can lead to better results.

Tip 2: Encourage feedback from operators. Their insights can identify areas for improvement.

Investing in modern packing solutions enhances production. However, staying current with trends is important. As the industry evolves, continuous education is essential.

Quality Control Mechanisms in Sauce Packaging Processes

Quality control in sauce packaging is critical for maintaining product integrity. Effective quality mechanisms ensure that sauces are free from contamination and meet safety standards. Key features often include automated inspection systems that detect packaging defects. These systems can identify issues such as seal integrity and proper fill levels. Visual inspections are vital as well. They ensure that every bottle or pouch meets the required specifications.

To enhance quality control, manufacturers implement real-time monitoring. Sensors can track variations in temperature and humidity during packaging. This data helps prevent spoilage before the product reaches consumers. However, relying solely on technology poses challenges. Human oversight is still necessary. Errors can occur in calibration or during system malfunctions. Regular maintenance and training for staff are essential for mitigating these risks.

Packaging processes must also prioritize consumer feedback. This information can reveal more about product preferences and potential issues. Addressing customer concerns leads to improvements in quality control. Overall, a balanced approach of technology and human interaction creates a robust quality control framework. It's a process of continuous reflection and adjustment.

Sustainability Considerations in Sauce Packing Machine Design

Sustainability is becoming critical in the food industry. Sauce packing machines are now designed with eco-friendly principles. They aim to reduce waste and energy consumption while maintaining efficiency. According to a 2022 report by the Food Packaging Association, 70% of consumers prefer brands with sustainable practices.

New designs focus on recyclable materials. This shift allows companies to meet consumer demand for sustainable packaging. Many sauce packing machines now use bio-based plastics and minimize excess material. However, the integration of these materials can lead to challenges in durability. Companies must find a balance between sustainability and functionality.

Energy-efficient technologies are also a priority. For instance, machines that reduce energy consumption by up to 30% are emerging. This reduction significantly lowers the carbon footprint. Yet, some manufacturers struggle with the initial investment in these advanced technologies. The long-term benefits often outweigh the costs, but change is slow. Companies must continuously reflect on their practices to align with sustainability goals while remaining competitive.

Related Posts

-

Top 10 Automatic Liquid Packaging Machines for Efficient Production

-

Top Benefits of Using an Automatic Packaging Machine for Your Business

-

Essential Tips for Choosing the Best Chips Making Machine for Your Business

-

What is a Cane Juice Machine and How Does It Work for Your Business

-

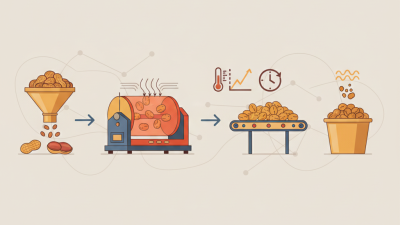

What is a Peanut Roasting Machine and How Does It Work

-

How to Choose the Best Fish Cutting Machine for Your Kitchen Needs