What is a Peanut Roasting Machine and How Does It Work

In the realm of nut processing, the peanut roasting machine stands out as a pivotal piece of equipment that transforms raw peanuts into a deliciously toasted snack. Renowned industry expert, Dr. Emily Carter, a leading figure in food technology, emphasizes its significance by stating, "The peanut roasting machine is not just a tool; it encapsulates the artistry of flavor enhancement and texture perfection." This poignant observation highlights the machine's crucial role in elevating the sensory qualities of peanuts, making them more appealing to consumers.

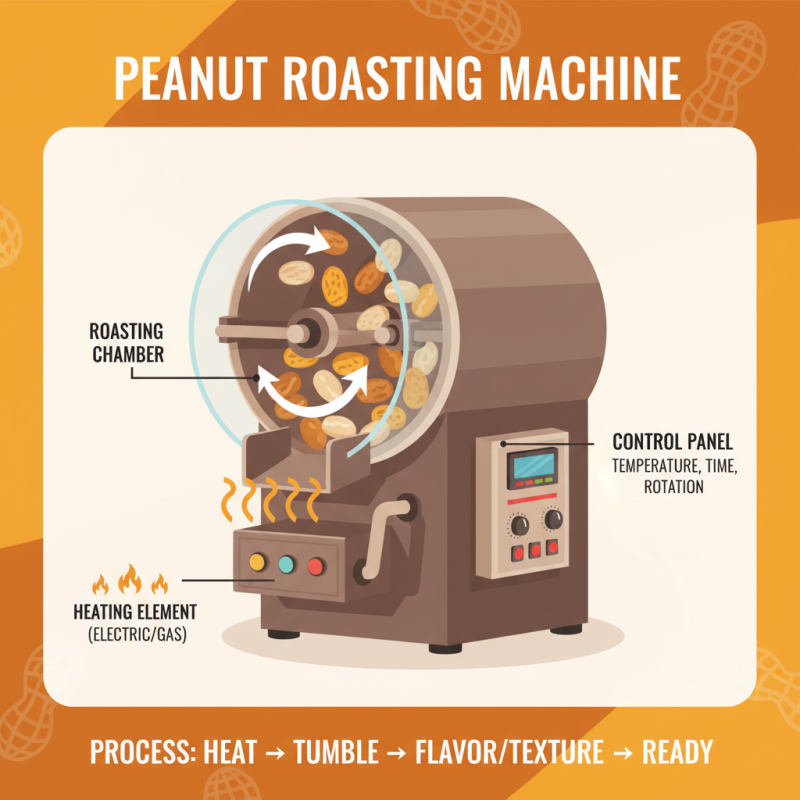

Understanding how a peanut roasting machine operates is essential for those in the food production sector. These machines utilize a combination of heat and airflow to evenly roast large batches of peanuts, ensuring optimal flavor and consistent results. The intricate process involves precise temperature control and timing, which are vital for achieving the perfect roast. As the industry evolves, advancements in technology continue to refine the efficiency and efficacy of these machines, positioning them as indispensable assets in peanut processing facilities.

As we delve into the mechanisms and benefits of peanut roasting machines, it becomes clear that they are central to maximizing the potential of peanut products. By harnessing the proper techniques and equipment, producers can deliver high-quality roasted peanuts that delight consumers and contribute to the growth of the snack industry.

What is a Peanut Roasting Machine?

A peanut roasting machine is a specialized piece of equipment designed for the efficient roasting of peanuts. It operates on the principle of applying controlled heat to the peanuts, allowing them to develop their characteristic flavor, aroma, and texture. The machine can vary in size and design, often serving both small-scale and industrial roasting needs, making it suitable for various applications, from artisanal nut shops to large food manufacturing plants.

The working mechanism of a peanut roasting machine typically involves a heating element that generates hot air or direct heat, which is circulated around the peanuts as they tumble within a roasting chamber. This process ensures even roasting, preventing some peanuts from becoming overly cooked while others remain underdone. Many machines also feature adjustable time and temperature settings, giving operators the ability to customize the roasting process to achieve the desired level of doneness and flavor enhancement. With advancements in technology, modern peanut roasting machines may also include features such as automatic cooling systems and digital controls to improve efficiency and consistency in peanut production.

The History and Evolution of Peanut Roasting Machines

The history of peanut roasting machines is a fascinating journey that showcases the evolution of food processing technology. Traditionally, peanuts were roasted using simple methods, such as placing them on hot stones or in earthen pots over an open flame. This process was labor-intensive and required skill to achieve the desired flavor and texture. As demand for roasted peanuts grew, especially in the snack food industry, the need for more efficient and consistent roasting methods became apparent.

With the advent of the Industrial Revolution in the 18th and 19th centuries, mechanical innovations paved the way for the development of the peanut roasting machine. Early models were often hand-cranked and made from basic materials, allowing for greater control over the roasting process. As technology advanced, these machines were refined to include features such as adjustable temperature controls and automated timers, enabling mass production while maintaining quality. The introduction of electric roasting machines in the 20th century further revolutionized peanut roasting, making the process faster, safer, and more reliable, ultimately transforming how peanuts are roasted and enjoyed across the globe.

Peanut Roasting Machine Production Over the Years

This chart illustrates the growth in sales of peanut roasting machines from the year 2000 to 2023. It highlights the increasing popularity and demand for peanut roasting machines over the years, reflecting advancements in technology and production methods.

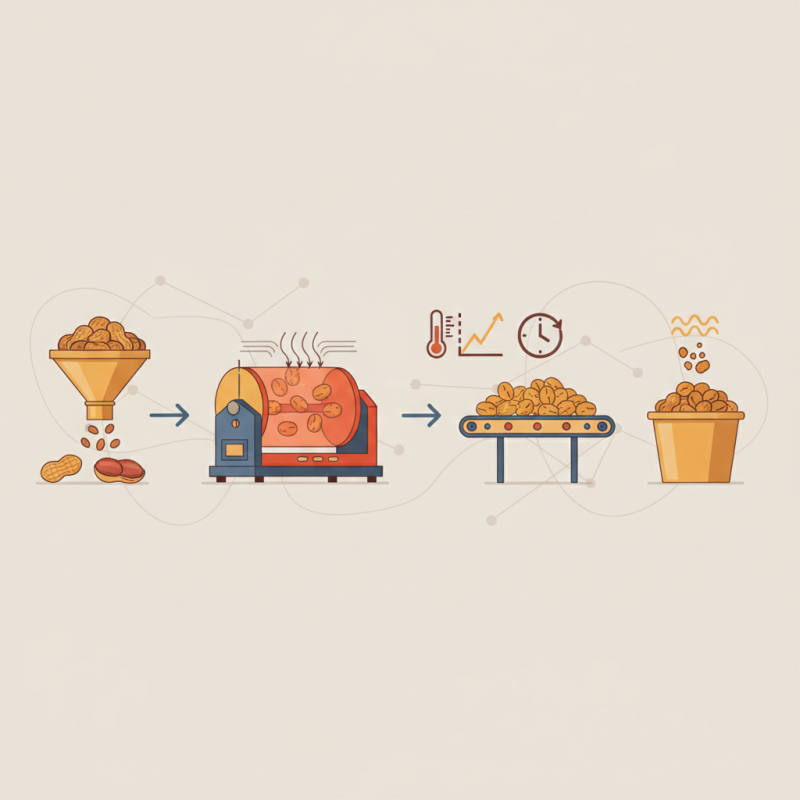

How a Peanut Roasting Machine Works: Key Components Explained

A peanut roasting machine is designed to heat peanuts until they achieve the desired flavor and texture, making them ready for consumption or further processing. The key components of a peanut roasting machine include the roasting chamber, heating element, and control panel. The roasting chamber is where the actual roasting occurs, typically equipped with a rotating mechanism to ensure even roasting. The heating element can vary depending on the machine's design, ranging from electric heaters to gas burners, providing the necessary heat to cook the peanuts through conduction and convection.

The control panel allows operators to adjust the temperature and roasting time, enabling customization based on peanut variety and desired roast level. Additionally, many machines come with cooling mechanisms to quickly reduce the temperature after roasting, preserving flavor and texture. Understanding these components and their functions is crucial for anyone interested in the peanut roasting process.

Tips: Always monitor the roasting time closely to avoid over-roasting, as this can lead to bitterness. Additionally, consider experimenting with different temperature settings to find the perfect roast for your specific taste preferences. Regular maintenance of the machine, including cleaning the roasting chamber and checking the heating elements, will ensure optimal performance and longevity.

Different Types of Peanut Roasting Machines Available

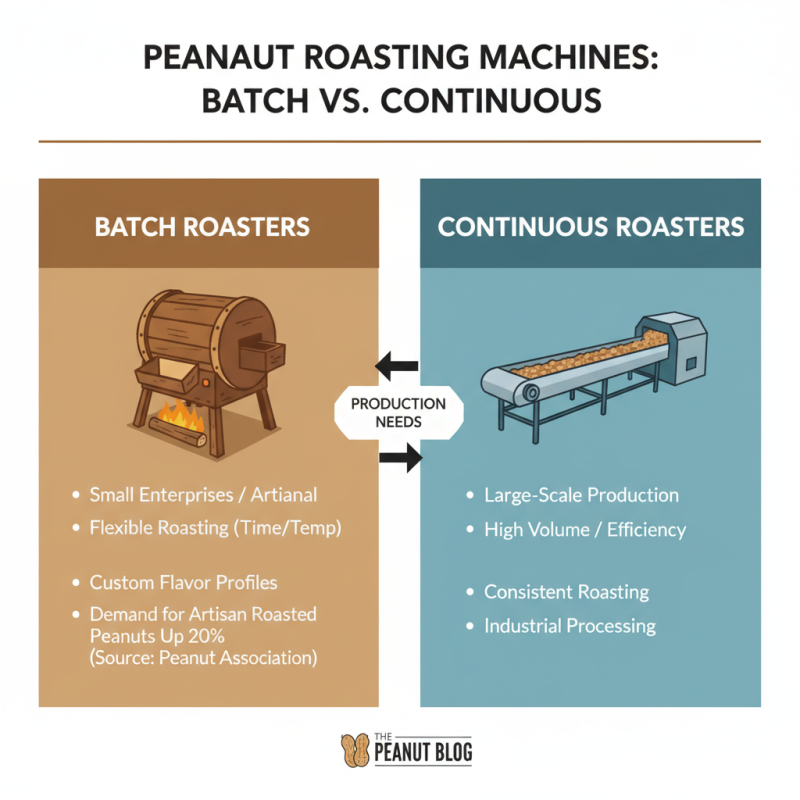

Peanut roasting machines come in various types, catering to different production needs and methods. Among the most common are batch roasters and continuous roasters. Batch roasters, which are often used by small enterprises or artisanal producers, allow for flexibility in roasting times and temperatures, ensuring that each batch can be tailored to achieve a desired flavor profile. Data from the Peanut Association indicates that the demand for artisan roasted peanuts has risen by approximately 20% in recent years, showcasing a trend toward customized processing methods.

In contrast, continuous roasters are designed for large-scale operations where efficiency and output are critical. These machines process peanuts in a steady flow, significantly increasing productivity while maintaining consistent roasting quality. A report from Market Research Future suggests that the market for peanut processing equipment is projected to grow at a CAGR of 5.1% from 2021 to 2027, driven by the rising consumption of peanuts and peanut-based products globally. Innovations in technology have also led to the development of more advanced roasting machines equipped with automation, temperature control systems, and energy-efficient designs, further enhancing throughput and reducing operational costs.

Overall, choosing the right type of peanut roasting machine depends on production scale and desired outcomes, reflecting broader industry trends and consumer preferences. As the peanut processing market continues to evolve, understanding these different machines can help producers align their operations with market demands.

Applications and Benefits of Using a Peanut Roasting Machine

Peanut roasting machines play a crucial role in the food industry, enhancing the flavor and texture of peanuts for various applications. One of the primary benefits of using a peanut roasting machine is its ability to produce consistently roasted peanuts that meet quality standards. According to a recent industry report, the global peanut processing market is expected to grow at a CAGR of 4.5% from 2021 to 2026, largely driven by the increasing demand for roasted peanuts in snack foods, confectioneries, and culinary applications.

In addition to improving flavor, the roasting process also enhances the nutritional profile of peanuts. Roasting can increase the bioavailability of certain antioxidants and phytochemicals, making them more beneficial for health. Data shows that roasted peanuts contain higher levels of certain essential nutrients, such as folate and niacin, which are vital for maintaining overall health. Furthermore, the ability to control roasting parameters can lead to tailored products that meet specific dietary needs, appealing to health-conscious consumers in a growing market for nutritious snacks.

Beyond nutritional benefits, peanut roasting machines offer operational advantages, including energy efficiency and reduced processing time. Advanced technology in these machines allows for uniform heating and precise temperature control, resulting in minimal energy wastage. A study highlighted that using modern roasting systems can reduce energy consumption by up to 30%, aligning with industry efforts to promote sustainability. This efficiency is critical for manufacturers aiming to balance quality production with economic viability in an increasingly competitive marketplace.

What is a Peanut Roasting Machine and How Does It Work - Applications and Benefits of Using a Peanut Roasting Machine

| Feature | Description |

|---|---|

| Heating Method | Electrical, gas, or wood-fired heating options |

| Operational Capacity | Ranges from small batch (5 kg) to large industrial (500 kg) capacities |

| Temperature Control | Precision temperature regulation for optimal roasting |

| Cooling System | Integrated cooling systems to prevent over-roasting |

| Applications | Peanut processing for snacks, oil extraction, and culinary uses |

| Benefits | Improved flavor, enhanced shelf life, increased market value |

| Energy Efficiency | Modern machines designed for lower energy consumption |

| User Interface | Digital controls for easy monitoring and adjustments |

| Maintenance | Low maintenance requirements with readily available parts |