Essential Tips for Choosing the Best Chips Making Machine for Your Business

In the competitive world of snack production, selecting the right chips making machine is crucial. Renowned industry expert, John Smith, emphasizes, "The success of your snack business hinges on efficient machinery." Making the right choice can lead to increased productivity and better product quality.

Many aspects of chips making machines create confusion. Manufacturers offer various models, each with unique features. Understanding your specific business needs becomes essential. You might find that a high-speed machine works best, or perhaps a smaller unit fits well for artisan production.

However, the overwhelming choices can lead to impulsive decisions. Taking the time to research is important. Reflect on what truly matters for your business, whether it’s volume output, energy efficiency, or ease of maintenance. Each of these factors will influence your bottom line and affect customer satisfaction. When navigating this complex landscape, balancing quality and cost is key.

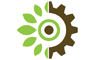

Understanding Different Types of Chips Making Machines Available in the Market

When choosing a chips making machine, understanding the different types available is crucial. There are primarily three categories: continuous fryers, batch fryers, and vacuum fryers. Each type serves unique production needs. For instance, continuous fryers can process up to 1,200 kilograms per hour. They are ideal for large-scale operations, but setup and maintenance can be complex.

Batch fryers, on the other hand, accommodate smaller volumes. They offer flexibility and are often preferred by startups. Reports indicate that businesses using batch fryers can reduce energy consumption by 30%, making them economical. However, they may not keep up with high demand.

Vacuum fryers operate at lower temperatures. This results in healthier chips while preserving flavors. However, they require a higher initial investment. Research shows that the market for vacuum frying technology is expected to grow by 12% over the next five years. It's essential to review production goals and capacity needs carefully. The right machine must align with your business strategy. Some manufacturers may exaggerate claims. Critical evaluation is necessary to ensure the best choice.

Key Specifications to Consider When Selecting a Chips Making Machine

When selecting a chips making machine, certain specifications are crucial. The capacity of the machine is a primary factor. It determines the output. Higher capacity machines churn out larger quantities. This can boost productivity. However, if your business is small, a smaller machine may suffice. Assess your production needs carefully.

The type of material also matters. Machines may construct from stainless steel or other materials. Stainless steel is often preferred due to its durability and ease of cleaning. Consider energy efficiency ratings, as this affects operating costs. A machine with higher efficiency saves money in the long run. However, achieving balance can be challenging.

Automation features can enhance productivity. Machines with advanced automation reduce labor costs. Yet, automated machines might require more initial investment. Maintenance needs should not be overlooked. Machines with complicated parts may need frequent repairs. This could lead to downtime. Evaluate the trade-offs between price, functionality, and maintenance. Be mindful of these factors to avoid costly mistakes.

Bar Chart of Key Specifications to Consider When Choosing a Chips Making Machine

Evaluating Production Capacity: Meeting Your Business Demands

When choosing a chips making machine, evaluating production capacity is crucial. A machine that seems efficient on paper may not meet your actual production needs. Start by estimating your daily output requirements. Consider your peak production times and calculate the volume you need. A machine that can’t keep up will cause delays and impact sales.

Different machines offer varying capacities. Some can produce a few kilograms per hour, while others may exceed hundreds. Think about the size of your operation. Have you accounted for future growth? If your production increases, will your current machine still suffice? Often, businesses underestimate their capacity needs. It leads to regrets down the line.

Also, think about maintenance and downtime. Machines with higher capacities may also require more maintenance. A busy schedule can’t accommodate frequent breakdowns. Understand the trade-offs between speed and reliability. Often, choosing a slightly lower capacity with consistent performance is smarter than chasing high output numbers.

The Role of Energy Efficiency in Choosing Chips Making Machines

When selecting a chips making machine for your business, energy efficiency should be a priority.

Machines that consume less energy can significantly reduce operational costs. Look for equipment with energy-saving features. These can lower electricity bills and decrease your carbon footprint.

Tip: Check for machines that offer adjustable settings. This allows you to optimize power usage based on production needs. For instance, lower energy settings can be great during off-peak hours. Efficient machines also tend to have a longer lifespan. They require less maintenance, saving you time and money in the long run.

Consider the production capacity of the machine. An efficient machine should match your business scale. If it’s over-capacity, it wastes energy. If it’s under-capacity, you risk inefficiencies. Assess your production goals before making a decision. A balance is essential for both performance and sustainability.

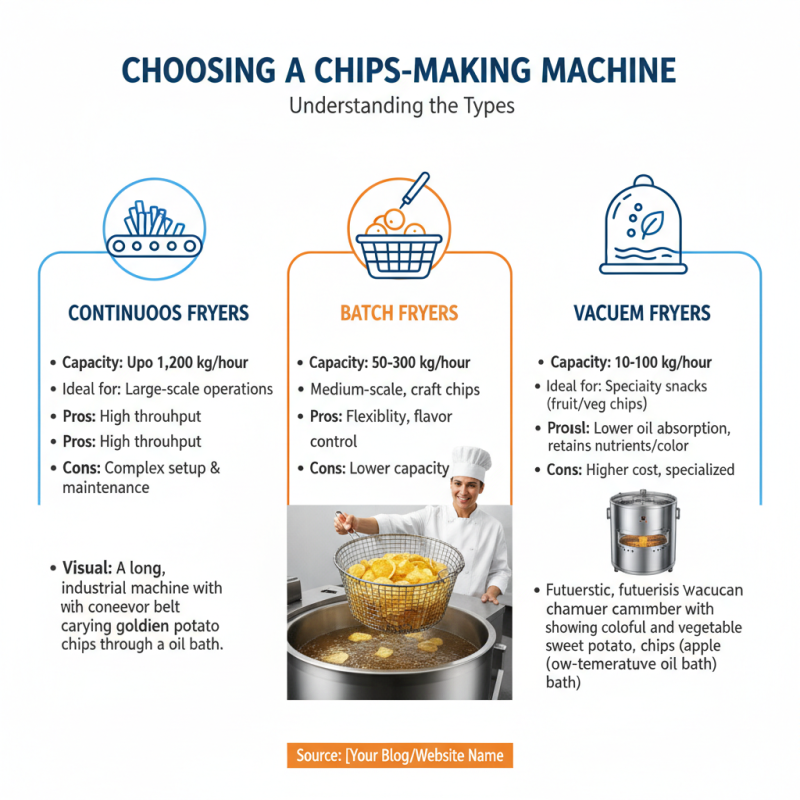

Cost Analysis and Return on Investment for Chips Making Equipment

When investing in chips making equipment, cost analysis is crucial. You need to consider the initial purchase price. This is just the starting point. Installation, training, and maintenance also add to the total cost. A machine that seems affordable may have hidden expenses.

ROI is another critical factor. Understand how to measure it effectively. Calculate potential profits based on production capacity. If the machine can produce 1,000 bags daily, what revenue can that generate? Compare this to operating costs. It’s essential to track your numbers carefully.

Consider the lifespan of the equipment. Will it need upgrades soon? A high-quality machine may have a higher upfront cost, but it can save money long-term. Evaluate all these aspects before making a decision. Some choices might require adjustments down the road. Be prepared to refine your approach as you learn more about your business needs.

Related Posts

-

What is a Cane Juice Machine and How Does It Work for Your Business

-

How to Choose the Right Liquid Packing Machine for Your Business Needs

-

Top Benefits of Using an Automatic Packaging Machine for Your Business

-

How to Choose the Best Commercial Peanut Butter Machine for Your Business

-

How to Choose the Best Fish Cutting Machine for Your Kitchen Needs

-

What is a Peanut Roasting Machine and How Does It Work