Top Tips for Choosing an Automatic Packing Machine?

Choosing the right automatic packing machine can elevate production efficiency significantly. According to a recent industry report by MarketsandMarkets, the global packing machine market is projected to reach $43.3 billion by 2027, growing at a CAGR of 4.2%. This highlights a growing reliance on advanced machinery in manufacturing processes.

The integration of automatic packing machines streamlines operations. Companies can reduce labor costs and enhance speed. However, selecting the right machine isn't straightforward. Factors such as product type, packaging material, and production volume require careful consideration. Not every machine suits every business.

Investing in an automatic packing machine is a critical decision. The consequences of poor choices can impact your bottom line. Therefore, weighing options and seeking expert guidance is crucial for achieving optimal results. There’s always room for improvement in selecting the right technology.

Understanding the Different Types of Automatic Packing Machines

When choosing an automatic packing machine, understanding the various types is essential. There are several categories, including flow wrappers, case packers, and form-fill-seal machines. Each type serves different packing needs. Flow wrappers are popular for snacks and baked goods. They efficiently wrap items in a protective film, enhancing shelf life.

According to industry reports, the global automatic packing machine market is projected to reach $12 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.5%. This growth indicates the rising demand for automated solutions. Form-fill-seal machines, for instance, have gained traction due to their versatility. They create packages from a roll of film, filling and sealing in one process. Many companies prefer these machines for their reduced material waste.

However, not all machines suit every application. Some might struggle with items of varying shapes and sizes. Potential buyers must assess their products first. Packing machines require an initial investment. It is crucial to analyze the long-term benefits carefully. Regular maintenance is also vital to avoid operational downtime. This decision impacts overall production efficiency significantly.

Evaluating Production Requirements for Packing Machines

When evaluating production requirements for packing machines, consider your specific needs. Understand the product dimensions and weights. Different products require different types of packing solutions. For example, bags, boxes, or shrink-wrapping might be necessary. Analyzing the type of packaging can help streamline the process.

Speed is another crucial factor. Determine how many items you pack per hour. This will influence the machine’s design and capabilities. Sometimes, businesses underestimate their production needs. It’s essential to project growth and future demands. Rushing this step may lead to costly mistakes later.

Think about maintenance and support too. Machines may require regular servicing to function optimally. Assess the availability of spare parts and service providers in your area. Sometimes, cheaper options may lead to higher long-term costs. Reflecting on these factors is vital for making a sound investment in automatic packing machines.

Top Tips for Choosing an Automatic Packing Machine

This chart illustrates the key factors to consider when choosing an automatic packing machine based on production requirements. The data shows the importance of different factors in percentage terms.

Key Features to Look for in an Automatic Packing Machine

When selecting an automatic packing machine, understanding essential features is critical. Efficiency is paramount. According to a report by MarketsandMarkets, the demand for packaging machinery is projected to grow at a CAGR of 7.8% from 2021 to 2026. Automatic machines significantly reduce manual labor and accelerate production lines. Evaluating the machine's speed and output capacity is vital. Many machines can operate at over 100 packs per minute, showcasing impressive productivity.

Another critical feature is versatility. The machine should accommodate various product types and pack sizes. A flexible packing system can significantly enhance production capabilities. Typically, users face difficulties when machines cannot handle diverse products seamlessly. This can lead to delays and increased costs. Additionally, consider the technology used in the machine. Features like servo-driven systems can enhance precision and reduce errors, but they can be complex to operate. Assessing user-friendliness is essential to minimize training time.

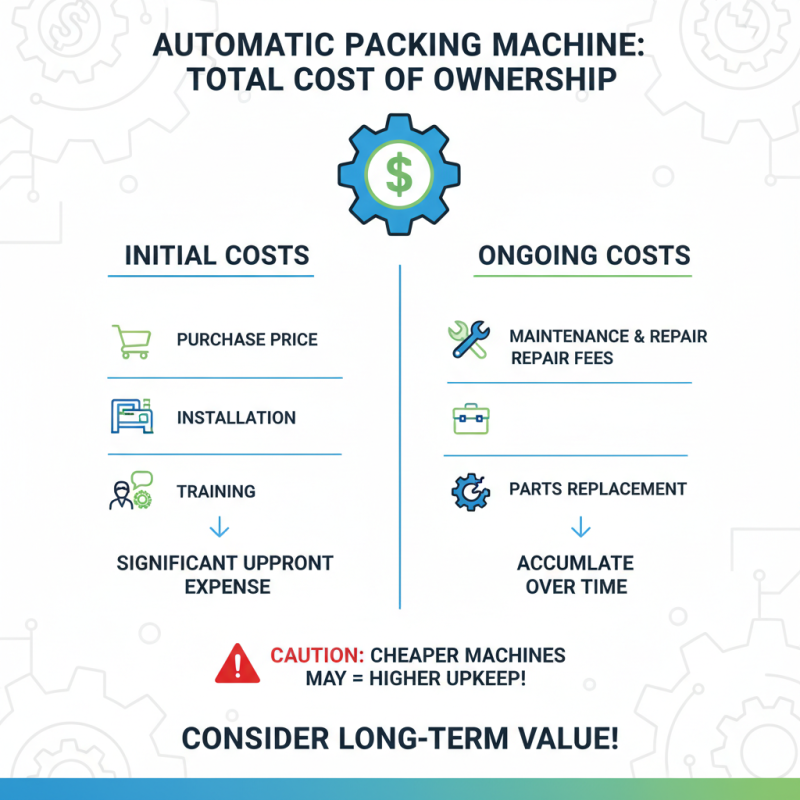

Lastly, maintenance requirements cannot be overlooked. Opt for machines with accessible components. An industry study indicates that over 30% of downtime is caused by unforeseen machine failures. Regular maintenance can reduce these risks. However, some machines may provide only limited support or unclear maintenance guidelines. This can lead to confusion and potential operational disruptions. A proactive approach to machine selection is crucial for long-term success.

Top Tips for Choosing an Automatic Packing Machine

| Feature | Importance | Considerations |

|---|---|---|

| Speed | High | Determine the desired output rate. |

| Versatility | Medium | Ability to handle various packaging types. |

| Size | High | Ensure it fits your production space. |

| Ease of Use | High | User-friendly controls and operation. |

| Maintenance | Medium | Consider the frequency and ease of servicing. |

| Cost | High | Balance initial investment with long-term savings. |

| Safety Features | High | Ensure compliance with safety standards. |

Assessing Budget and Cost-Effectiveness of Packing Solutions

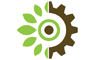

When assessing the budget for an automatic packing machine, it’s crucial to consider total cost of ownership. Initial expenses can be significant. This includes the purchase price, installation, and training. However, ongoing costs matter too. Maintenance and repair fees can accumulate. Sometimes, cheaper machines require more upkeep. This can lead to unexpected expenses.

Cost-effectiveness is about balancing price and performance. A low-cost machine may not suit all products. Sometimes, it can't keep up with production demands. Efficiency matters greatly in shipping and turnover. Investing in a reliable machine, though pricey, can yield better returns. Evaluate the longevity of equipment. A durable machine can save costs in the long run.

Reflecting on your specific needs is essential. Not every packing solution fits every business. Analyze your product type and packaging requirements. You might discover that a mid-range option works best. Take time to conduct thorough research. Seek feedback from others in the industry. This step can often provide new insights and clear perspectives. The goal is to make informed decisions that truly benefit your operation.

Considering Maintenance and Support for Packing Equipment

When selecting an automatic packing machine, maintenance and support are vital considerations. According to a 2022 industry report, about 30% of packing machinery failures occur due to inadequate upkeep. Regular maintenance can significantly extend the lifespan of these machines. Neglecting this aspect can lead to unexpected downtime, affecting productivity.

Support is equally important. A machine may perform well initially, but ongoing technical assistance is essential. Research indicates that companies with proactive support services reduce machine errors by up to 25%. This can translate into substantial savings, as every hour of stopped production can cost businesses thousands of dollars. Reliable support ensures that any issues are promptly addressed.

Choosing a machine without considering these factors can lead to regrets. If maintenance schedules are unclear, it creates uncertainty. This, in turn, can lead to poor performance. Evaluate the support offered. Ask for service response times. This knowledge can prevent operational disruptions. After all, a machine is only as good as the support it receives.

Related Posts

-

What is a Peanut Roasting Machine and How Does It Work

-

How to Choose the Best Fish Cutting Machine for Your Kitchen Needs

-

Top Benefits of Using an Automatic Packaging Machine for Your Business

-

How to Choose the Best Commercial Peanut Butter Machine for Your Business

-

Essential Tips for Choosing the Best Chips Making Machine for Your Business

-

Top 10 Automatic Liquid Packaging Machines for Efficient Production